التقييم

-

د.علاء غيتة

جراحة تجميل

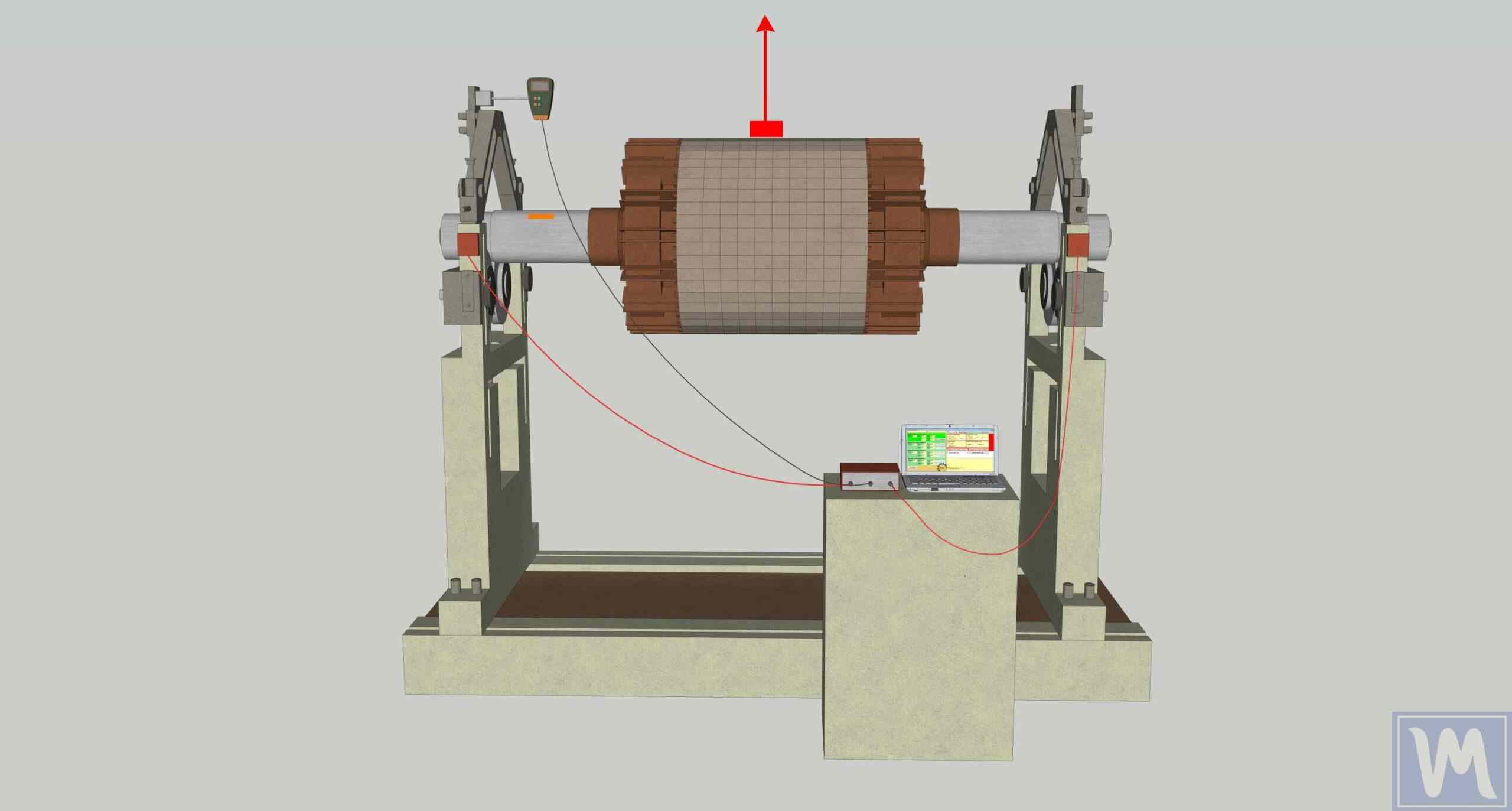

Balanset-1A: A Compact Solution for Rotor Balancing

Rotor balancing is a critical process in maintaining the efficiency and longevity of industrial machinery. The Balanset-1A device offers an innovative approach to this essential maintenance task, providing a compact and portable solution for engineers and technicians. In this article, we explore the features of Balanset-1A and discuss how to perform a vibration analysis on a drive shaft effectively.

Why Choose Balanset-1A?

Balanset-1A is designed for convenience and mobility, making it a perfect choice for field operations and on-site maintenance. Its rugged case ensures the device can withstand the rigors of industrial environments, allowing professionals to conduct rotor balancing outside of stationary conditions with ease.

Intuitive Software Interface

The Balanset-1A connects seamlessly to a laptop, offering an intuitive software interface with step-by-step instructions for setup and balancing. Users simply follow the on-screen prompts, allowing the program to automatically calculate corrective weights and their installation angles. This user-friendly approach ensures that even those new to vibration analysis can operate the device efficiently.

Multifunctionality and Precision

Combining the functionalities of a vibrometer and a balancing device, the Balanset-1A provides comprehensive insights into machinery health. Its vibrometer mode allows users to monitor overall vibration, build spectra, and analyze harmonics, offering a complete picture of the mechanism's condition. The balancing mode enables precise calculations for weight and angle adjustments in either one or two planes, with measurement accuracy up to В±1В° for phase and В±5% for vibration indicators.

Performing Vibration Analysis on a Drive Shaft

Vibration analysis is a vital part of maintaining drive shafts and ensuring their optimal performance. Here's a step-by-step guide to performing a vibration analysis:

- Initial Inspection: Before beginning, inspect the drive shaft for visible wear and tear. Ensure that the shaft is clean and properly mounted.

- Setup: Install vibration and phase sensors at recommended locations on the drive shaft. Balanset-1A’s software will guide you through this process.

- Initial Measurements: Use the vibrometer mode to assess overall vibration levels. If the total vibration closely matches the rotational component, imbalance is likely a significant contributor.

- Further Investigation: If total vibration significantly exceeds the rotational component, inspect bearings, secure mounting, and check for rotor interference with fixed parts.

- Preliminary Balancing: For horizontally oriented shafts, manually rotate the rotor 90 degrees. If imbalance is present, the rotor will seek equilibrium. Add a balancing weight at the top point and adjust until the rotor remains stationary in any position.

- Final Balancing: Follow the Balanset-1A’s software instructions to complete the balancing process, adjusting weights in one or two planes as necessary.

Conclusion

The Balanset-1A stands out as a reliable, user-friendly tool for rotor balancing and vibration analysis. Its portability, intuitive software, and precision make it an excellent investment for both large-scale industrial operations and smaller workshops. By integrating the Balanset-1A into your maintenance routine, you can enhance machinery performance and reduce downtime effectively.

[b]Contact Information:[/b] For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu. Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera. Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/. Buy Balanset-1A on Amazon

Balanset-1A OEM on Etsy

السعودية

السعودية